Industrial Floor Coatings in New Jersey

Polyaspartic Coatings for Industrial Flooring in NJ

When you operate an industrial facility, your floors need to handle serious wear from heavy machinery, constant traffic, chemicals, and temperature changes. At Fortress Floor Coatings, we install industrial floor coatings in New Jersey designed to protect your concrete, improve safety, and keep your operations running smoothly.

That’s why we use a polyaspartic double-coat concrete system built for strength, longevity, and real-world industrial use. The first layer penetrates deep into the concrete, sealing cracks and surface imperfections while creating a strong bond. The second layer forms a tough, abrasion-resistant surface that withstands heavy machinery, forklifts, pallet traffic, and daily wear.

This two-layer system not only extends the life of your concrete floors but also provides excellent resistance to chemicals, moisture, and temperature changes, making it a smart solution for the wide range of industrial facilities in New Jersey.

Benefits of Polyaspartic Industrial Floor Coatings

Polyaspartic coatings are one of the most reliable solutions for industrial concrete floors. Compared to traditional epoxy, they offer faster curing, greater durability, and a finish that holds up under demanding conditions. When you choose polyaspartic industrial floor coatings, you get long-term performance, less maintenance, and a professional finish that doesn’t break down over time.

Enhanced Durability

Polyaspartic coatings are built to resist abrasions, impacts, and constant wear. They help protect your concrete from cracking, chipping, and surface damage caused by heavy equipment and daily operations.

Fast Curing Times

Polyaspartic coatings cure much faster than epoxy, allowing your facility to return to service sooner and minimizing operational disruptions while keeping projects on schedule.

Chemical Resistance

From oils and solvents to cleaning agents and industrial chemicals, polyaspartic coatings protect your floors from stains, deterioration, and costly concrete damage.

UV Stability

Unlike epoxy, polyaspartic coatings resist yellowing and discoloration when exposed to sunlight, which makes them ideal for both indoor and outdoor industrial concrete surfaces.

Ready To Upgrade Your Flooring?

Call us today to get your free estimate!

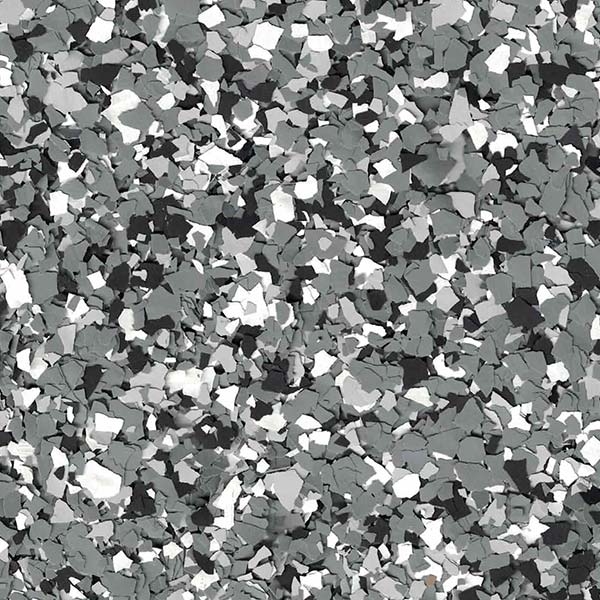

Industrial Floor Coating Colors & Finishes

Industrial flooring doesn’t have to look plain. Choose from a variety of colors, textures, and finish options to match your facility’s needs, improve visibility, or designate work zones. We’ll help you select a finish that balances performance, safety, and appearance.

Cabin Fever

Fortress

Madras

Slate Stone

Sandstone

Driftwood

Smoke

Domino

Our Industrial Floor Coating Process

We follow a proven, multi-step process designed specifically for industrial floor coatings. Every step focuses on proper preparation, strong adhesion, and long-term performance, ensuring your floors can withstand heavy equipment, chemicals, and daily industrial use.

Surface Preparation

Surface preparation is the foundation of a long-lasting industrial floor coating. We begin by mechanically grinding your concrete with professional diamond-grinding equipment to remove the weak surface layer and prepare the concrete for proper bonding. During this step, dust is controlled with industrial vacuum systems to keep your facility clean. We also address cracks, pits, and other damage and remove deep contaminants, such as oil or grease, when needed.

Base Coat Application

Once the surface is properly prepared, we apply two layers of polyaspartic coating to create a tough, abrasion- and chemical-resistant finish. This system is designed to withstand forklifts, heavy machinery, pallet traffic, spills, and temperature changes, all while maintaining a clean, professional finish.

Polyaspartic Topcoat Application

We then apply a high-quality polyaspartic topcoat that penetrates and seals the concrete. The topcoat strengthens the substrate and creates a strong bond between the concrete and the coating system, helping prevent peeling, lifting, or premature wear in demanding industrial environments.

Final Inspection, Curing & Quality Control

Before the project is complete, we perform a detailed final inspection to ensure uniform coverage, proper adhesion, and overall finish quality. Once approved, the floor is allowed to cure fully, leaving you with durable industrial floor coatings that meet our standards and are ready for daily operations.

Industrial Floor Coatings NJ Service Areas

We proudly serve all of New Jersey, including Bergen County, Passaic Valley, Monmouth County, Ocean County, and beyond. Wherever you are in the state, we deliver industrial floor coating solutions that work.

Morris County

Middlesex County

Essex County

Union County

Monmouth County

Hudson County

Ocean County

Somerset County

Bergen County

Gym Floor Coating FAQs

How long does it take to install a polyaspartic gym floor coating?

Most gym floor coating projects are completed in one day, depending on the size of your facility and the condition of the concrete. Polyaspartic coatings cure much faster than epoxy, so your gym can often reopen the same day or within 24 hours, minimizing downtime and disruption for members and classes.

Are polyaspartic coatings better than epoxy for gym flooring?

In most gyms, yes. Polyaspartic coatings cure faster, resist chemicals better, and handle temperature changes more effectively than epoxy. They’re also less likely to yellow, peel, or crack, making them ideal for New Jersey gyms with fluctuating seasons.

How do polyaspartic gym floor coatings handle dropped weights and heavy equipment?

Polyaspartic coatings create an impact-resistant surface that withstands dropped weights, sled pushes, and rolling equipment. While no coating replaces rubber lifting platforms in extreme weight zones, polyaspartic gym floor coatings provide excellent protection for most gym areas and reduce concrete damage over time.

Can polyaspartic gym floor coatings handle sweat, moisture, and humidity?

Absolutely! Polyaspartic coatings are non-porous and moisture-resistant, so sweat and water remain on the surface rather than soaking into the concrete. This helps prevent odor buildup, bacterial growth, and mold growth, keeping your gym cleaner and more hygienic.

Can polyaspartic gym floor coatings be used in locker rooms and entryways?

Yes, they’re a great option for locker rooms, hallways, and entryways where water and foot traffic are part of everyday use. We can also apply slip-resistant finishes to help improve safety when floors are wet.

How long do polyaspartic gym floor coatings last?

With proper care and maintenance, polyaspartic gym floor coatings can last 10–20 years or more. Their durability makes them a cost-effective, long-term solution for gym owners who want to avoid frequent resurfacing or floor replacement.

Discover More Commercial Floor Coatings

Industrial